When Lead Went Dead

How Lead Solder was banned from plumbing. The use of lead to convey drinking water dates to the Roman Empire (the word plumber comes from the Latin name for lead – “plumbum”, hence its chemical symbol – Pb). Not surprisingly, the use of lead bearing solders to join copper water lines was the accepted approach for decades. By far the most common lead-bearing plumbing solder was 50/50 (nominally 50% tin and 50% lead).

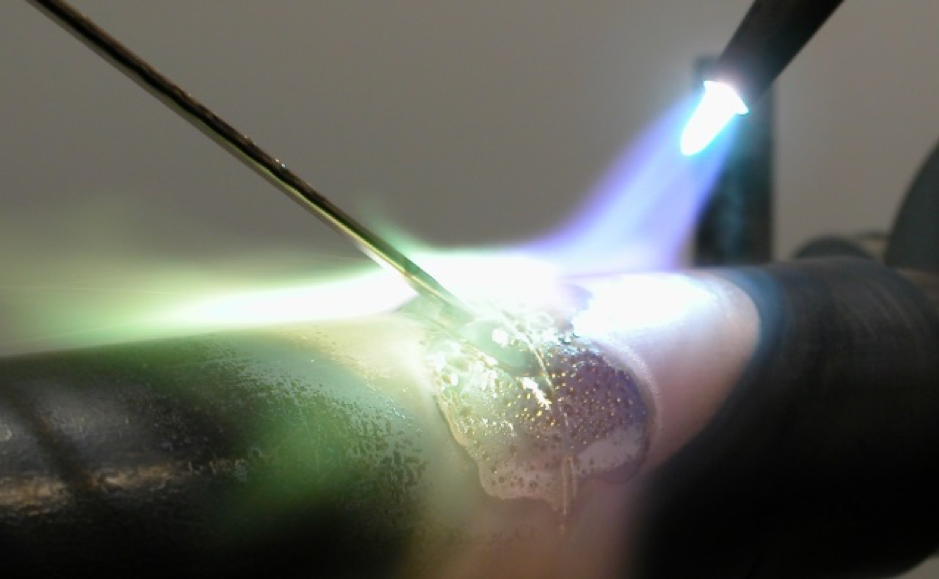

How Brazing Works – Capillary Action

One of brazing’s attributes is the ability of melted filler metal to flow between parts to produce a strong, leak-proof connection. This effect, capillary action, enables braze penetration between two surfaces. It makes it possible to join pipe or tube in the horizontal position and, despite gravity, in the vertical “up” position.

Did you know that you can solder an HVAC connection?

Solders are typically considered a plumbing product. But, did you know low-temperature tin/silver solders have higher strength and ductility than typical plumbing solders? This makes them suitable for most residential HVAC connections.