Factors to Consider When Choosing a Brazing Alloy

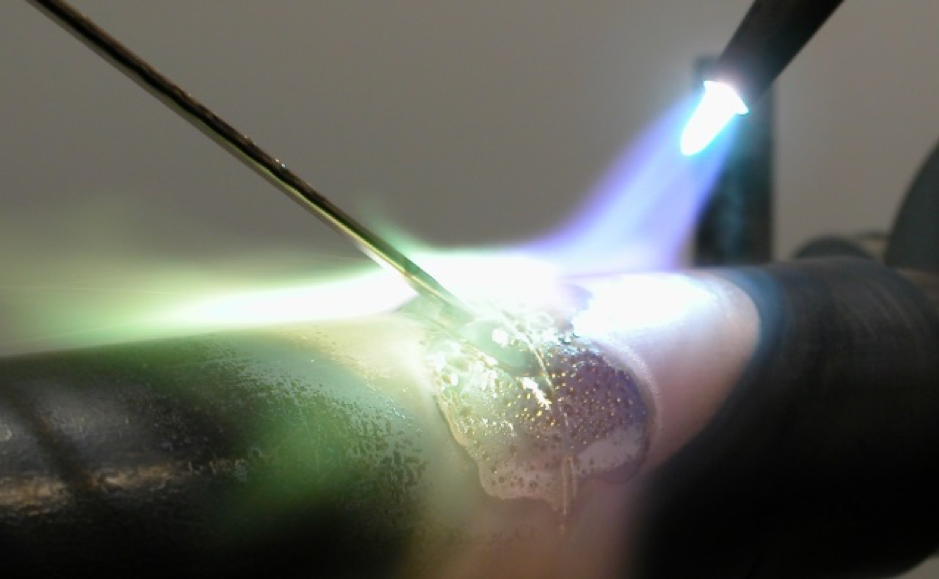

Brazing requires that the filler metal flow into a capillary between the two closely aligned base metals to be joined. In the case of copper-phosphorus braze alloys – these base metals are usually copper or brass, and joint integrity is dependent on a number of factors in addition to the choice of filler metal.

Five misconceptions about flux

Bob Henson

At The Harris Products Group, we sell a lot of brazing and soldering alloys. Over the years we’ve noticed some misunderstandings about the importance of flux in producing a quality brazed joint. Here are the five most common misconceptions about flux.

Two-Stage Regulators

The basic function of a gas pressure regulator is to reduce unusable high pressure from the source to a lower usable delivery pressure. Two-stage regulators are designed to lower the high pressure in two stages. They require less readjustment and provide a more constant delivery pressure despite changes in inlet pressure. They are exceptionally well suited for high pressure cylinder applications.

What is solidus and liquidus and why is it important to brazing?

If you look at a list of brazing filler metals you’ll note many compositions and a variety of melting temperatures. The melting characteristics of brazing filler metal are an important aspect in filler metal selection. Here’s a brief outline of how alloys melt and the way to use this information to make the best selection.

What is the difference between Harris silver brazing fluxes and where is each one used?

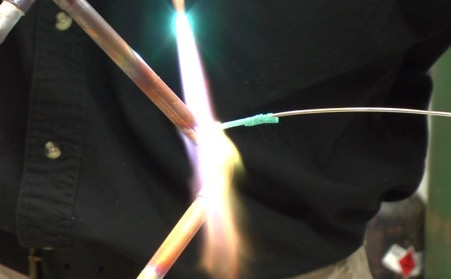

STAY-SILV WHITE BRAZING FLUX

This is a white paste flux that’s used for 90% of silver brazing applications. White flux is useful for brazing copper, brass, steel, stainless steel and nickel alloys. It has an active temperature range of 1050° -1600°F (565° – 870°C). Use it with the Safety-Silv® high silver brazing filler metals (AWS BAg series) on the above base metals, and the Stay-Silv® phos-copper-silver (AWS BCuP series) on copper to brass.

What metals can be brazed?

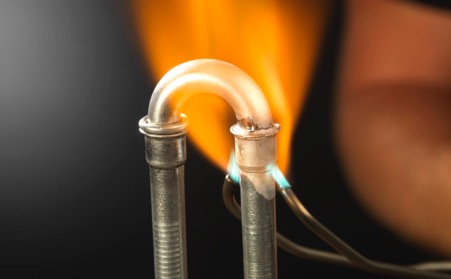

Many different types of metals can be brazed. Copper, and copper based materials like brass and bronze, are typically brazed with copper phosphorus silver alloys also known as American Welding Society (AWS) BCuP filler metals.

Which gas do you turn off first?

“Which gas do you turn off first?” We get this question a lot out in the field, and it’s a good one. This blog entry outlines our recommendations for proper shut down of an oxy-fuel torch.

Why is flux required when brazing brass and not required with copper to copper?

A fluxing agent (or a controlled atmosphere as found in furnace brazing) is required for all brazing and soldering applications. The purpose of the flux is to remove oxides from the base material and to prevent oxidation during the heating process, thus promoting the free flow of the brazing filler metal.