Solders are typically considered a plumbing product. But, did you know low-temperature tin/silver solders have higher strength and ductility than typical plumbing solders? This makes them suitable for most residential HVAC connections.

During brazing, copper is heated to over 1300°F. At this temperature copper softens with resultant weakening of the tube adjacent to the brazed joint. The low operating temperature of tin/silver solder does not overheat the tube so it retains its strength. We’ve conducted burst tests comparing results using brazed and soldered copper tube and fittings.

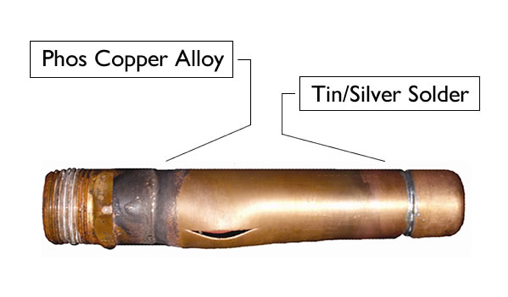

Note the distortion next to the brazed connection in the image below. Higher temperature brazed connections always fail adjacent to the braze. This failure occurs at a much lower pressure than those connections soldered with a tin/silver alloy. This makes tin/silver a better option than higher temperature phos/copper/silver braze alloys.

The lower tin/silver soldering temperature offers other advantages; a nitrogen purge is unnecessary during heating and you don’t need to protect temperature sensitive parts like valves or filter driers.

As with any HVAC procedure we encourage contractors to follow applicable local or national codes, as well as equipment manufacturer’s installation and service bulletins. Also, review job engineering documents to confirm if brazing is specified.

Christen Foltz is a Technical Sales Representative for Wholesale at Harris Products Group. She joined Harris in 2016 after graduation from Ohio State University.