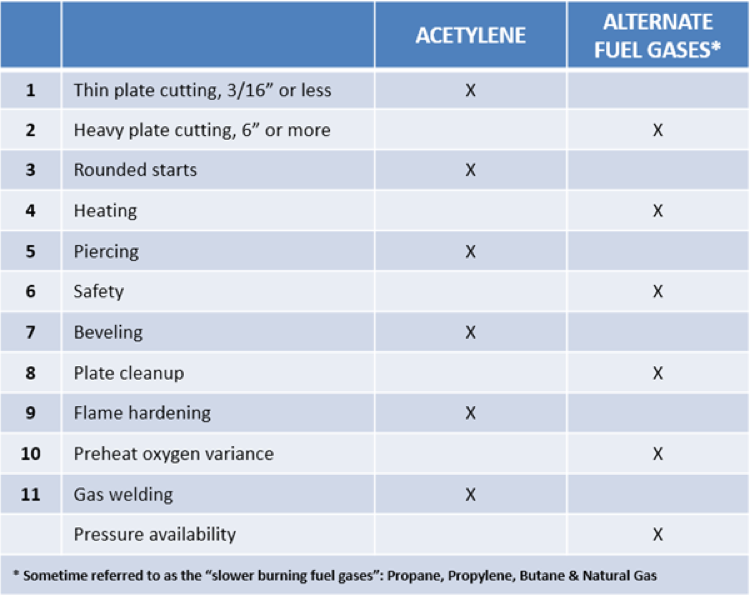

When selecting between acetylene and alternate fuels, there are several factors that need to be evaluated. While cost is certainly a consideration, it’s also important to know the characteristics of each gas. Choosing the wrong fuel gas for your application could end up costing you more in the long run. Here are some important characteristics of both gas types to help you make the best choice.

1. There are particular areas of flame cutting where one gas is preferred and is an advantage over the others. On very thin plates, 3/16″ or less, acetylene is preferred. The design of the equipment is such that the flame can be impinged to greater advantage than with slower burning gases.

2. The opposite is true for thicker plates with slower burning fuel gases.

3. On rounded edges, acetylene is preferred because of its flame impingement properties and its high flame temperature.

4. Heating with slower burning fuel gases has a distinct advantage because generally greater volumes can be made available and the majority of those fuels have higher BTU values per volume.

5. Piercing requires a concentrated high flame temperature and impingement properties, which makes acetylene the best gas for this application.

6. Generally alternate fuels are safer in uses because they are lower burning, require less shaded eye protection and have less of a tendency to flash back.

7. Acetylene is preferred for beveling due to the higher flame temperature and impingement properties. This drawback can be overcome with slower burning fuel gases by use of the Harris bevel attachment (Model S-98-C) which has a leading preheat tip.

8. Plate cleanup after cutting with gases other than acetylene is much easier because of their lower flame temperatures and the lesser tendency to impart carbon into the cut face surface.9. For flame hardening, acetylene is preferred due to its higher carbon content along with its higher temperature.

10. The slower burning fuel gases have a much wider preheat variance capability than acetylene.

11. Gas welding can only be performed satisfactorily with acetylene. This is primarily because of its unique ability to absorb and use the atmospheric oxygen around the molten steel during a welding operation creating an inert shield and preventing weld contamination.

12. Generally, higher supply pressures are possible (up to full cylinder pressure) to aid in providing higher fuel volumes to the torch when necessary. For safety reasons, acetylene can only be made available up to 15 psig.