Gas Welding

The American Welding Society defines gas welding as a group of welding processes wherein coalescence is produced by heating with a gas flame or flames, with or without the application of pressure, and with or without the usage of a filler metal. Gas welding involves the melting of a base metal and a filler metal, if used, by means of the flame produced at the tip of a welding torch. The molten metal from the plate edges and the filler metal, if used, intermix in a common molten pool and upon cooling coalesce to form one continuous piece.

In plain terms, gas welding is a method of joining steel by heating the surfaces to be joined to the melting point and allowing the two parts to fuse together with the addition of a filler rod where required. Normally, we think in terms of using a filler metal on all material 3/16″ thick or more. All steel to be welded should be cleaned prior to welding so that it is free of oil, grease, rust, scale, or other impurities which may affect the weld quality or tensile strength of the finished weld. Generally, only oxy-acetylene (in specific cases oxy-hydrogen) is recommended for oxy-fuel welding.

Braze Welding

Braze welding differs from gas welding in that the melting temperature of the filler metal being used is below that at which the base metal will melt, but at or above the melting temperature of the filler material. Braze welding differs from brazing in that the joint design for braze welding is similar or identical to that used in gas welding. Capillary action is not a factor in the formation of a bond.

While acetylene gas is always required as the fuel for gas welding, braze welding can be performed with the other fuel gases such as propane, natural gas, propylene, etc., as well as with acetylene. This is due to the fact that in braze welding there is addition of flux to perform the functions normally associated with pre-cleaning and the deoxidizing characteristic of the acetylene-oxygen flame.

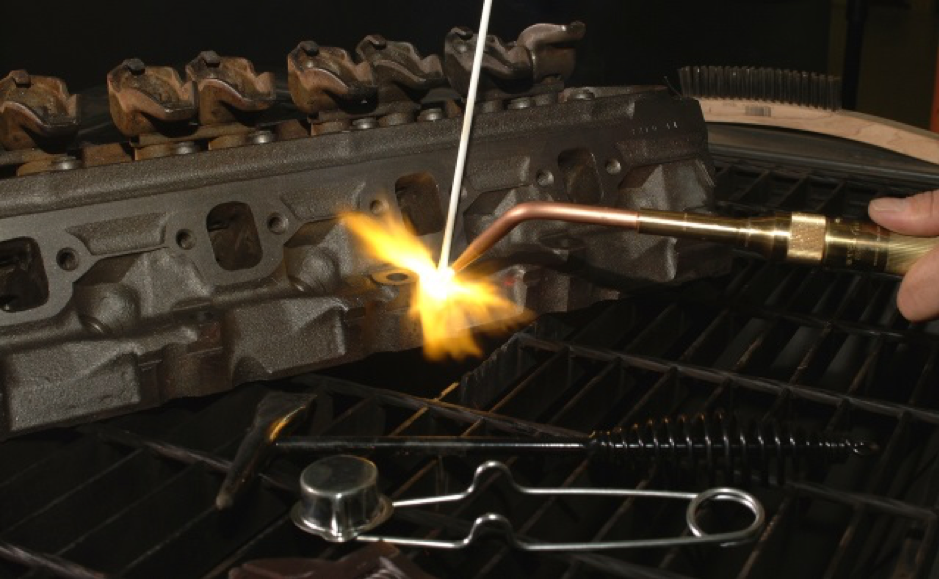

Braze welding is most commonly associated with joining of steels. In general, the filler material used is a low fuming bronze – either a bare rod which is dipped into a flux material or a bare rod with a flux coating on the rod itself. In actual practice, the steel to be joined is heated to an approximate dull red color at which point the low fuming bronze filler material is applied with the flux and it flows against the steel to be joined, creating a tight, adherent bond.

In general, the strength level of a braze-welded joint is lower than that of a gas-welded joint. The advantages of braze welding are:

- Lower heat input which results in less distortion.

- The steels to be welded do not have to be melted in order to create the welded joint.

- Dissimilar materials can be readily joined where this might not be possible with gas welding

Doug Perry

Doug Perry is a Technical Sales and Marketing Support Representative at Harris Products Group. With over 30 years of experience at Harris, Doug is passionate about teaching people about Harris products – how to use them, how to sell them and new cost-effective applications for them.