Harris Products Group

The basic function of a gas pressure regulator is to reduce unusable high pressure from the source to a lower usable delivery pressure. Two-stage regulators are designed to lower the high pressure in two stages. They require less readjustment and provide a more constant delivery pressure despite changes in inlet pressure. They are exceptionally well suited for high pressure cylinder applications.

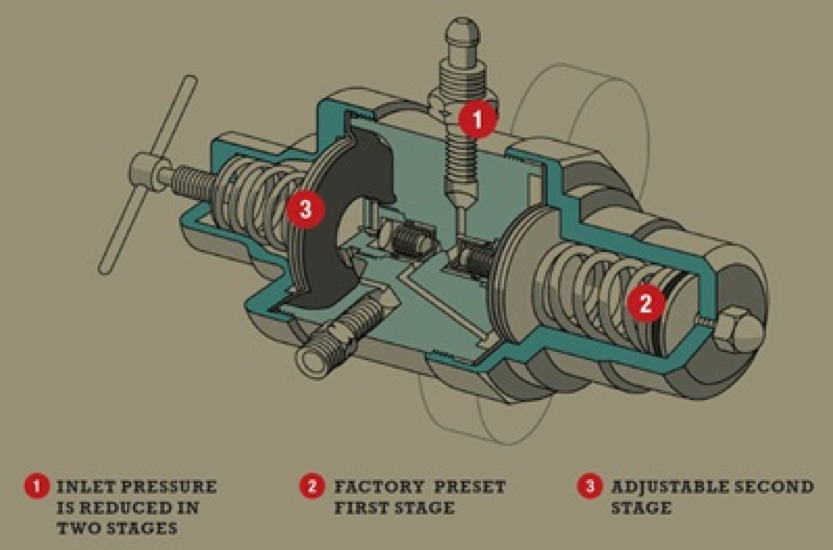

Operation of two-stage regulators

Two-stage regulators are two regulators built into a single regulator body. The first regulator (first stage) is preset at a non-adjustable pressure to reduce the incoming pressure to a lower pressure, referred to as the intermediate pressure. The second regulator (second stage) is adjustable within the desired delivery range.

These regulators incorporate all components of a single stage regulator. They also contain an additional stage to include a second pressure adjusting spring, diaphragm, and valve seat assembly. The first stage is not user adjustable. The pressure adjusting spring is “pre-compressed” at the factory. This allows the first stage to feed pressure to the second (adjustable) stage. The normal maximum delivery pressure for two-stage regulators is 500 PSI.

The second stage then performs in a manner similar to that of a single-stage regulator, except that the inlet pressure of the second stage is relatively constant. The two-step pressure reduction produces a final delivery pressure showing little effect from changes in cylinder pressure.

When is a two-stage regulator required?

- Applications where the delivery pressure rise from cylinder pressure decay cannot be tolerated.

- Situations where proper pressure is critical and the cylinders in use are in a remote or difficult to monitor location.

- Typically are not required when using gases from low pressure (<500 PSIG) sources.